How a Skydiamond is Created

Our diamonds are crafted in Britain and made unlike any other. Everything we need to create them comes from the sky–sun, wind, rain and something the world has too much of: CO₂

Born from the Sky. Crafted by Hand.

This isn’t factory-line technology. It’s a careful, constant craft. At our Sky Lab in Gloucestershire, our engineers – part scientists, part alchemists – fine tune every stage of the process with precision and care.

We harvest carbon straight from the atmosphere and lock it away forever in the purest form possible: a diamond.The water we use comes from captured Cotswolds rain. Wind and sun are the source of our energy: 100% renewable and provided by our sister company, Ecotricity.

This is innovation working in harmony with Mother Nature, creating beauty without compromise.

Step by Step Process

-

Step 1.

We extract CO₂ from the atmosphere, which we liquify and purify – an important step in ensuring the quality of our diamonds. With the CO₂ removed, the air released back into the atmosphere is cleaner than we found it.

-

Step 2.

We take rainwater collected from our factory roof and split it into oxygen and hydrogen using electrolysis.

-

Step 3.

CO₂ from the air and hydrogen from the rain are combined with biological single-cell life forms (the equivalent of a diamond sourdough starter) in a completely patented and bespoke process to create methane, which we feed into our diamond mills with a dash of nitrogen.

-

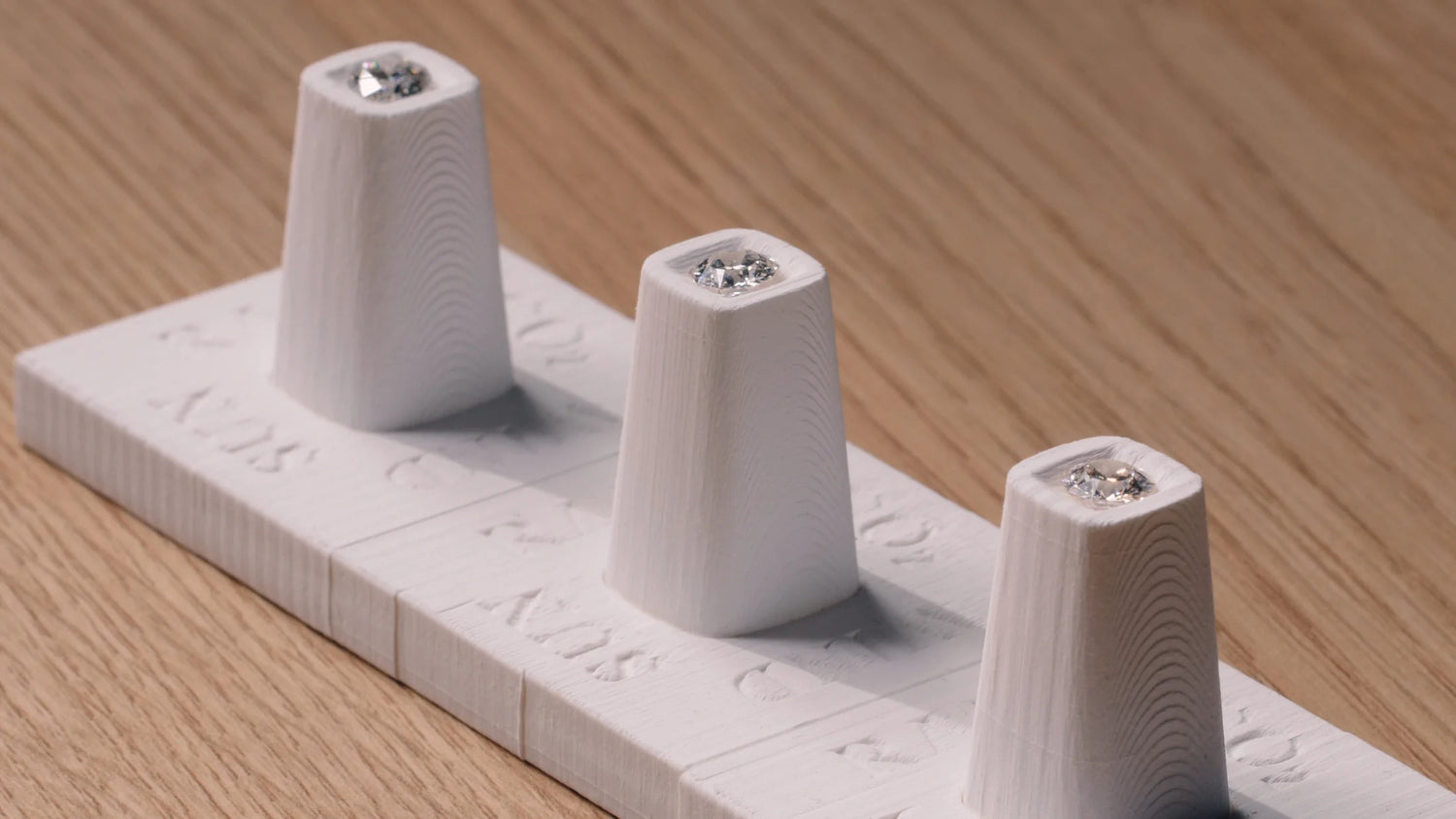

Step 4.

Inside our mills we grow our Skydiamonds on tiny diamond seeds (which we also make) in a ball of plasma running at about 1,000 degrees Celsius – roughly the temperature of the outer layer of the sun – using the renewable energy provided by the solar and wind power of our sister company, Ecotricity.

-

Step 5.

Several weeks later, our Skydiamonds have emerged. They are sent in batches to world class cutters and polishers in India; a woman's collective training and paying the female artisans the same as their male colleagues, while giving them flexible working hours to accommodate family commitments.

-

Step 6.

Our diamonds are certified using AnchorCert’s 4Cs for impeccable quality in colour, clarity, cut and carat. These hand selected stones are then set into our fine jewellery pieces in recycled precious metals, ensuring they reflect true beauty and your values.

Skydiamond sets a new standard in diamond creation

We’ve created the world’s first carbon-negative diamonds, powered entirely by nature’s elements and designed to last a lifetime.

Grown from the sky.

-

Grown from the sky

-

Made in the Cotswolds, England

-

World's only carbon negative diamond

Unparalleled Clarity, Independently Verified

We partner with UK-based AnchorCert Gemmological Laboratory, one of the world’s leading gemmology laboratories, to review our loose stones.

Our impact matters

Skydiamond was born to contribute to a planet-positive future, creating 'another way' without compromise on quality or beauty.

Diamond Brilliance without Destruction

Made in Britain using only nature’s elements– captured carbon, rainwater, wind and sun – our lab-grown diamonds show that sustainable luxury and cutting-edge design can exist together. They meet the same standards of quality and grading as any mined stone – without the destruction.

Liquid Silver: A SKYDIAMOND EXCLUSIVE

Liquid Silver is a lab-grown diamond featuring a rare silver-black colour created using sustainable electron beam technology. Certified as a colour not found in nature, it offers a striking alternative to traditional diamonds.

Skydiamonds Exclusive Cuts

Lab-grown diamond custom cuts from Skydiamond include four unique shapes—Stellar, Meteoric, Onda, and Nova—each crafted to maximise brilliance and inspired by nature’s beauty.